How IoT Can Improve Construction Industry

Construction is not the fastest sector in IoT adoption. Project managers and investors are still wary about implementing the technology — some don’t know how to use it, others doubt its efficiency.

However, recent statistics show that it’s only a matter of time before IoT in construction becomes a must-have technology. The emerging innovation will have a part to play in waste management and employee safety improvement, construction costs reduction, and helping match properties against the requirements of prospective tenants.

In this post, we will examine the impact of IoT and construction integration in the construction field, its main applications, and its benefits.

Table of Contents

- What Problems Does IoT Solve in the Construction Industry?

- Solutions IoT can Offer For a Construction Business

- Benefits of IoT in Construction

- Examples of IoT Devices in Construction

- IoT Construction Solution with Digiteum

What Problems Does IoT Solve in the Construction Industry?

With the growth of urbanization and population density, the construction industry is one of the key contributors to the world’s well-being. According to statistics, by the end of the year construction will account for 13.2% of the global GDP.

The efficiency and profitability of construction directly impact the global economy. Although the industry is constantly evolving and new management practices are introduced, there are plenty of pain points in the fields managers and contractor teams have to deal with.

Here are the most pressing construction challenges the IoT for the construction industry can help mitigate:

Skills and labor shortage

Construction was one of the industries hit the hardest by the recession. With thousands of workers leaving their jobs and never coming back, the skills gap we are facing ten years later is enormous. In 2020, as more boomers working in construction consider retirement, there aren’t enough young skilled professionals to replace them.

According to the JOLTS survey, the field is now short 350,000 workers.

Concerned governments are considering multiple ways to handle the situation — throwing apprenticeship camps, attracting professionals from other industries, or integrating those who don’t feel welcome (women, for example) into the industry.

IoT-based automation is a way to make sure all pending projects are completed efficiently until more workforce enters the field.

On-budget and on-time project delivery

Struggling to complete projects on time has been a long-standing issue in construction. However, it’s increasingly more relevant now, when the growing complexity of construction plans makes it harder to anticipate delivery timeline and completion costs.

The introduction of IoT can improve the precision of estimates, increasing the confidence of construction business owners, managers, and investors.

Assessing team productivity and project profitability

The construction market is highly saturated. As a result, project managers need to beat competitors on the market, both by time and quality of completed work.

To make sure all resources of the construction process are used efficiently, business owners need to find new ways to monitor their teams. As most workers choose how to plan workdays and take breaks with no fixed schedule, meeting deadlines becomes increasingly more challenging.

Additionally, statistics indicate a dire need to cut worker waiting time, as the delivery of materials, moving between construction locations reduces the efficiency of the project.

Safety issues

Construction is known for one of the higher fatal injury rates worldwide. The common causes of workplace fatalities include:

- Falls from heights;

- Protective equipment failure;

- Injuries from repetitive motion;

- Electric shock;

- Trench collapse.

Although there are protocols and safety checklists that would help prevent workplace injuries, workers are rarely aware of them and fail to comply with the guidelines. IoT could help site managers provide the workforce with real-time education and reduce the number of injuries and medical-care-related expenses in the field.

Waste management

Construction business owners are obliged by the law to dispose of debris and recycle waste. Fuel costs for logistic operations, the need to document waste-disposal, and determining the most efficient recycling practices are important tasks for construction managers.

When it comes to waste management, the following objectives are the most pressing ones for project managers:

- Creating a feasible disposal plan;

- Adopting zero-waste, sustainable construction practices;

- Educating the workforce on sustainability;

- Disposal of different types of waste;

- Reporting.

Read: Benefits of smart water management using IoT

Outdated legacy systems

Finally, holding on to outdated technology slows down the construction industry exponentially. Obsolete hardware-software systems are expensive to maintain, lead to missed financial opportunities, reduce employee productivity, and make it harder to assess business efficiency.

In construction, digital transformation is a slow, incremental process — partly because most decision-makers are a part of a generation that is not used to operating digital tools, partly due to low tech-savviness among employees.

To have the upper hand, construction managers can no longer hold on to outdated systems — adopting innovative technologies will allow business owners to have control over management and competitive advantage within the customer base.

Solutions IoT can Offer For a Construction Business

The impact of the challenges described above can be minimized once the Internet of Things is introduced to the field. Here are the objectives construction companies using IoT reach by adopting the technology.

Project progress tracking

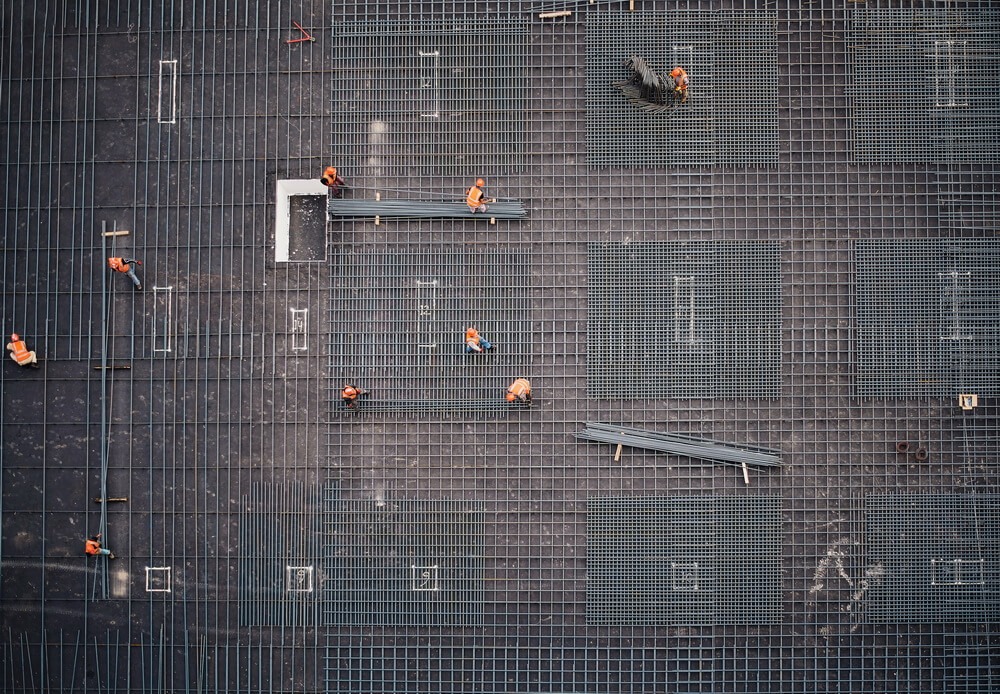

Using wearables, business owners can track employee movements, ensuring that the team’s working time is used efficiently. Additionally, connected fleet management systems help project managers keep tabs on material deliveries, improving the precision of deadline estimates.

By gathering real-time data about the progress of the project, construction managers will be able to identify the causes of setbacks and optimize the team’s day-to-day operations.

Monitoring the construction site

By implementing a range of sensors — noise, vibration, motion, and others — construction site managers can ensure safety in the area, predict and minimize the damage dealt by natural disasters, and respond to on-site accidents promptly.

Ensuring employee safety

Monitoring security and safety on large construction sites is not easy — human agents don’t have the reaction speed nor needed data to predict and prevent potential intrusions. IoT-enabled tags allow business owners to track the integrity of materials and equipment.

A system of connected sensors will enable environment monitoring to ensure that workers aren’t exposed to hazardous substances. IoT wearables can detect physical manifestations of distress — an elevated pulse rate, blood pressure, and others.

Being able to predict and prevent job-site issues will help business owners reduce the cost of accident management.

Remote equipment control and people management

By connecting building machinery to the web, business owners can manage the construction process remotely. IoT-empowered remote equipment control will facilitate the construction progress in areas that aren’t accessible for humans, are polluted, or dangerous to be in.

Wearable computing innovations, like Google Glass, improve the efficiency of remote employee management using IoT for construction equipment monitoring. A team leader will be able to instruct employees and manage constructions seeing the site from a worker’s point of view.

Read: The era of smart building using IoT

Facilitating day-to-day task management

Poor project maintenance practices often result in a higher cost of project completion. Outdated tech systems don’t allow business owners to track all assets efficiently, monitor the performance of equipment and schedule up-to-date repairs, plan maintenance stops.

Integration of the IoT in construction business offers managers a steady stream of real-time data that comes in handy during all kinds of decision-making — task planning, resource allocation, reporting, negotiation with investors, etc. Having on-demand access to relevant data improves team communication, protects teams from making unfounded decisions, enables real-time asset tracking.

Waste management

Other than having to oversee waste management for the sake of compliance with governmental regulations, disposing of debris regularly allows property owners to create more space on the construction site and reduce the risks of hazards.

Numerous IoT solutions for construction industry help improve waste management, some of which directly benefit construction. For instance, business owners can take advantage of the following solutions:

- Sensor-based tools for monitoring on-site trash levels;

- Determining how waste loads vary across the year and optimizing the operating mode to prevent debris pile-ups;

- Calculating the most efficient routes for waste collectors to reduce recycling and disposal costs;

- Offering business owners real-time waste management data for the sake of precise reporting.

Benefits of IoT in Construction

Adopting IoT in construction industry activities is neither a one-step process nor a cheap one to complete. That’s why, in order to complete digital transformation, business owners need to clearly understand the benefits of adopting innovation.

Here are the advantages of IoT integration in construction:

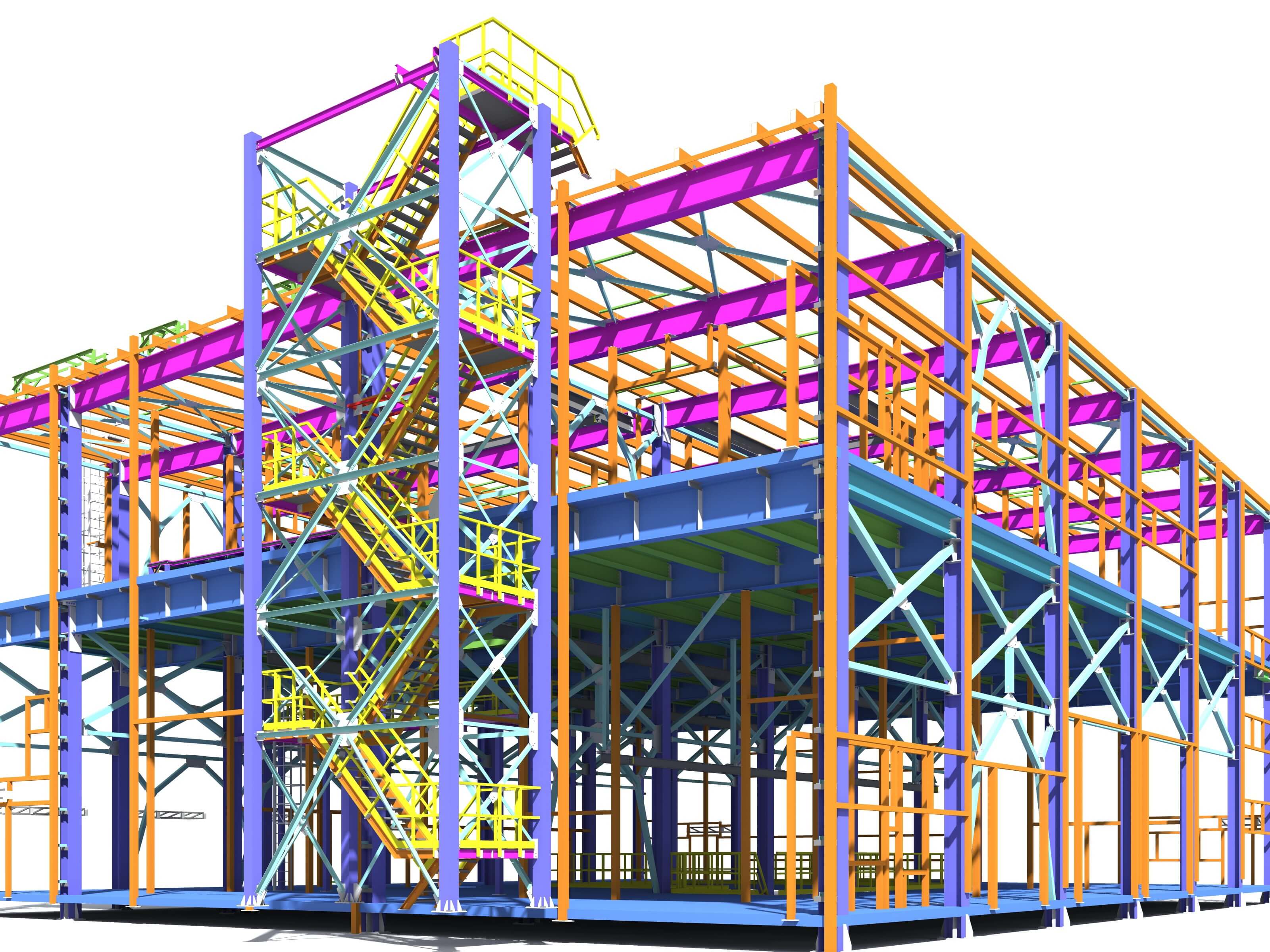

- Adopting Building Information Modeling. BIM refers to creating a digital version of the project. Many construction managers work with Building Information Modeling software that allows building a project’s digital model based on real-time construction and maintenance data. IoT is changing construction by providing a steady flow of relevant data, which when used in BIM can be shared with all stakeholders involved in the process and represent the insights visually in a dashboard.

- Reducing project costs. IoT devices help site manages keep track of daily expenses, monitor resource-efficiency of construction by tracking supply and assets. The Internet of Things reduces project costs by ensuring timely delivery of new equipment and other resources — this way, the entire team uses its time efficiently and a business manager doesn’t need to extend the crew’s contracts before the project is complete.

- Improving employee safety. The Internet of Things helps provide real-time guidance using connected wearables, monitoring the working environment and ensuring no workers are exposed to dangerous substances, tracking the worker’s physical well-being thanks to heart rate, body temperature, and other sensors.

- Predictive maintenance. In construction, predictive maintenance technologies are adopted to track the state of heavy equipment — lifts, excavators, and others. By attaching sensors to track fuel consumption or brake temperature to a machine, business owners can identify performance issues at the earliest stages and repair the equipment before it breaks down and triggers project downtime.

- Improved waste management efficiency. Measuring trash levels with a sensor-equipped device will allow construction managers to create a flexible schedule of waste disposal activities. This way, product managers can ensure they are not hiring waste disposal professionals when the dumpster is not full — such careful waste disposal control will improve the cost-efficiency of the process. Making sure that no waste is left on site, finding the reason for trash pile-up, and optimizing routes to waste disposal sites to reduce fuel costs are the tasks IoT is capable of handling. Implementing these will reduce operating costs as well as the volume of waste generated by construction works.

- Facilitated project management. Being able to collect worker, equipment, environmental, and other types of data facilitates the project manager’s decision-making. The Internet of Things helps educate the workforce as well, ensuring the crew can find answers to all questions on their own, as opposed to bothering the manager. Using an IoT platform to pinpoint patterns about working productivity, risks and threats, or project expenses will improve the precision of estimates and lay the groundwork for creating realistic strategies.

Examples of IoT Devices in Construction

Understanding the benefits of IoT devices in construction is crucial. After business owners realize how innovative technologies can move your project forward, they might be wondering if there’s a practical IoT application in the construction industry.

Here’s a review of some widely used IoT tools in construction:

1. Wearables

How wearable technologies can improve construction:

- Warning the crew by making high-pitched noises when a worker is close to a dangerous zone;

- Track workers’ vitals and remind them to take a break when their bodies are close to exhaustion;

- Assist emergency workers by determining the real-time location of an injured worker;

- Offering workers real-time instruction on how to complete work tasks safely and efficiently.

Examples:

- Smart Cap — a wearable device that tracks brain waves to monitor worker fatigue;

- Triax — a device that tracks the number of workers on each building in real-time, assisting project management;

- Hololens — a wearable allows construction workers to get real-time access to a 3D plan of a property, thus improving the efficiency of their actions and smoothing the learning curve.

2. Remote equipment management systems

How remote equipment management systems improve construction:

- Handle construction tasks in hard-to-access zones;

- Track the state of equipment remotely;

- Detect and prevent security, performance, and other issues.

Examples:

- Hyundai Construction Equipment — this monitoring system gives project managers a full, 360-degree view of the site from any angle of the machine — a lift, an excavator, etc.

- Remote Eye — a technical assistance system that helps track the performance of the equipment and instruct on-site workers in real-time.

3. Predictive maintenance systems

How predictive maintenance systems improve construction:

- Help prevent unscheduled maintenance expenses;

- Offer accurate machine performance data;

- Prevent machine downtime.

Examples:

4. Asset tracking tools

How asset tracking tools improve construction:

- Improves on-site security, ensure the integrity of equipment;

- Helps business owners locate needed materials easier;

- Monitors the efficiency of material usage;

- Generates real-time reports.

Examples:

- Atmel — a GPS tracking platform that offers real-time location data on construction equipment and materials.

- Ayantra Asset Management — a product for monitoring lifts, excavators, and other heavyweight equipment.

- Blackberry Radar — a tool for real-time equipment monitoring and reporting.

IoT Construction Solution with Digiteum

If you want to design an IoT solution for your construction project, reach out to Digiteum. Our software developers have built projects for multiple industries — including healthcare, finance, education, and others.

We design scalable architectures — wearables, sensor-based platforms, BLE trackers, and more. Construction managers can use these tools to manage their projects, improve the lifespan of equipment, and monitor worker efficiency.

To onboard a team of skilled developers for a IoT project development, leave us a message — a project manager will get in touch with you right away.