How to Use IoT (Internet of Things) in Logistics Industry: Successful Use Cases

Logistics management requires monitoring multiple activities at once — supply chain, warehousing, transportation, and so on. There are dozens of factors that can influence the process itself and cause delays. To streamline processes and increase customer satisfaction, industry leaders and decision-makers embrace innovation and evaluate the cost-benefits of using Internet of Things for logistics process optimization.

Internet of Things, among other technologies, provides businesses with tools for planning, monitoring, and heightening the security of all operations.

In this post, you’ll learn about how IoT works in custom logistics software development services and helps managers enhance efficiency, improve safety and cut operational costs. We will also talk about modern IoT applications in logistics and how industry experts implement the technology.

Companies use IoT to improve logistics processes — both in inventory management software development and beyond. The Global IoT in logistics market is expected to surpass $100 billion by 2030 and strengthen the role of Internet of Things and big data technologies for location management, inventory, and fleet management.

What are the objectives of investing in IoT logistics solutions and integrating connected technology into operations? As a rule, businesses implement Internet of Things in logistics with the following goals in mind:

Contact Digiteum

1. Improved security and theft detection

Connected applications increase the control over who enters the warehouse at any given time, help track all items, and alert a business manager in case something goes missing. Examples of IoT-powered security applications are connected CCTVs, apps that allow warehouse managers to block the doors of the facility remotely, IoT logistic tracking applications that help monitor deliveries, assets, and more.

2. Higher employee safety

Unreliable machinery and untimely maintenance may put people at risk. The Internet of Things’ effects on logistics include employee protection by detecting equipment issues long before they are noticeable. By tracking equipment conditions in real-time and predicting wear and possible damage, connected systems help reduce risks associated with employee safety.

Tracking wearables powered by IoT sensors help significantly increase the response time in case something happens to an employee. A wearable immediately detects a critical change in vitals and transfers the data to a dedicated platform that alerts the manager and even calls an ambulance.

3. End-to-end product tracking

Increasing the transparency of the delivery process is the primary objective business managers want to achieve by integrating IoT solutions for logistics.

Being able to track the product all the way from the warehouse to the customer’s doorstep increases the manager’s confidence that all stages of the supply chain are completed smoothly.

It also boosts the client’s trust in the brand and saves support agents a ton of time as customers no longer request delivery status updates from customer support.

4. Providing business managers with advanced analytics

Thanks to a broad range of applications and advantages of big data visualization and analytics tools, Internet of Things provides business managers with a big-picture view of the way all operations are handled.

By collecting data from sensors and presenting it in a concise, understandable way, IoT offers a holistic approach to logistics management.

Here are just a few things logistics managers can effectively monitor using IoT tracking and data analytics tools:

- The number of items in the warehouse via real-time asset tracking;

- Conditions in the warehouse, including temperature, humidity, light, etc.;

- Environmental conditions during deliveries;

- Employee and fleet performance.

Real-time delivery and inventory monitoring improve the quality of planning and budget allocation. The datum provided by IoT logistics applications helps managers always stay on top of what’s happening at every stage of the logistics process, detect inefficiencies and reduce waste.

5. Improving delivery

There are plenty of ways for Internet of Things to improve delivery management. RFID tags and connected GPS sensors help business managers track shipping all the way to its final stage. Also, thanks to connected sensors, logistics managers can get real-time location data to ensure the weather or other environmental changes will not jeopardize the delivery.

Logistics and transportation operations have always been associated with risks connected to the lack of control over weather conditions, high odds of scams, and a wide range of assets to manage. With the Internet of Things, logistics can finally become a fully controlled domain, where all the factors that could negatively impact the delivery process can be either neutralized or avoided.

In a nutshell, these are the benefits of using the Internet of Things in transportation and logistics.

Reliable vehicle tracking

Internet of Things helps businesses track the location of each vehicle, compare routes and find the most cost-efficient and sustainable delivery plans. Being highly aware of the ins and outs of the delivery process helps company owners evaluate employee performance and incentivize best practices, proactively react to problems on the road, and manage them effectively thus reducing losses and risks.

Reduced shipping costs

Automated order processing and status updating help companies cut the number of employees in charge of shipping, reducing overall operating costs. Using connected bots for last-mile delivery helps cut costs exponentially, as well as increase customer satisfaction. Amazon has been benefitting from autonomous bots and drop-shipping lockers for years, improving the convenience and sustainability of deliveries and generating profit.

Improved supply chain planning

Internet of Things applications provide businesses with multi-faceted data — how much time it takes to sell a given amount of products in the inventory, how to optimize deliveries, what vendors have better track records, which distribution centers have higher conversions. As a result, managers can plan operations and predict the outcome of business decisions rather accurately.

Learn more about IoT use cases for supply chain

People safety and employee monitoring

One of the most important benefits of IoT in logistics is improved people safety. Smart devices and wearables used in logistics help business managers to monitor the staff’s physical condition and estimate risks. There are sensor-based applications that help protect employees from exposure to toxic substances and monitoring tools that alert drivers if they are not adhering to safety practices.

There are even devices that can track an employees’ routines and evaluate staff’s performance based on the data. Using these insights, managers get a better understanding of employee efficiency, detect issues with time management or planning, and better align processes.

Product safety and improved transportation conditions

Many IoT device development projects in logistics are focused on anti-theft goals — connected hardware to detect intrusion, sensors for real-time asset tracking, alarm systems, smart fences and tracking systems for facility management using IoT. A business manager will be able to find an IoT solution for logistics that provides an increased inventory and end-to-end supply chain visibility, protects from scams, product theft, or tampering.

Internet of Things offers a ton of benefits for logistics companies. That’s why there are more than a few successful Internet of Things in software for logistics. The most widespread IoT use cases in logistics are:

1. Inventory tracking systems

Inventory tracking systems assist logistics managers in planning re-stocking and distributions.

Thanks to connected sensors, company owners will be able to ensure the products are stored safely, save time by being able to instantly locate a needed item, and minimize human errors. The connected system implemented at Amazon is proof of how technology can improve asset tracking and warehouse management.

2. Predictive analytics systems

Predictive analytics solutions help business managers make informed decisions regarding warehouse management and supply chain planning.

Such tools are used for laying out the shortest delivery routes, detecting early signs of deficient equipment, and reminding staff when it’s time to replace equipment components.

Predictive analytics systems increase the productivity of warehouses and cut delivery costs. Amazon’s ‘Anticipatory Shipping’ is a bright example of using IoT in logistics industry for predictive analytics and smart delivery planning.

3. Location management tools

With IoT in transportation and logistics, company managers can keep track of the real-time location of each vehicle, delivery statuses, and the estimated time needed to complete the process.

Location management tools help logistics companies:

- Improve the accuracy and automate asset tracking;

- Eliminate traffic-induced time losses;

- Increase vehicle management efficiency thanks to fleet tracking and smart parking solutions using IoT;

- Ensure vendors comply with the obligations set in their contracts.

4. Drone-based delivery

Drones are an efficient way to speed up and automate deliveries. In logistics, they can be used to improve navigation within the warehouse, provide customers with instant in-store deliveries, and solve last-mile delivery issues.

Once it is more commonplace, drone-based delivery will significantly cut operational costs and reduced the amount of workforce needed to keep high customer satisfaction rates.

Amazon is actively exploring the concept of drone-based delivery. This innovation is still in the making — hopefully, in a few years, drone-based delivery will become the next big thing in retail.

5. Automated vehicles

Automated trucks will become major innovation and application of IoT in logistics and transportation, McKinsey estimates. It is indeed likely that logistics companies will be among the pioneers in self-driving vehicle adoption and the ones to benefit the most from using IoT for logistics modernization.

Using AVs helps business managers have more control over the delivery process, reduce the impact of human error, and benefit from machine intelligence.

Smart vehicles help choose the most convenient and sustainable routes, adjust the temperature and other properties within the vehicle to store products in a favorable environment, and gather important data to help managers further improve route management and delivery processes.

Global logistics and transportation companies actively adopt IoT and use custom supply chain software to make their operations more effective, cost-efficient, and sustainable. Here are a few impressive examples of IoT in logistics from industry leaders: DHL, Nippon Express, DB Schenker, and Maersk.

DHL

Undoubted leader of global logistics, DHL uses IoT and wearables to create a safer work environment for on-site employees. DHL’s regional distribution center in Singapore integrated a monitoring system with connected beacons and wearables to track employees’ rest levels, better align breaks and working schedules and prevent fatigue. Using location data, the system maps employees on site and sends proximity alerts to prevent collisions and accidents.

Nippon Express

Nippon Express teamed up with Accenture and Intel to develop an effective system for tracking shipment through the entire supply chain. The goal was to enable better security, product safety and traceability for shipping pharmaceutical products and make sure no counterfeit medications would infiltrate the supply chain.

DB Schenker

DB Schenker set a goal to connect an entire supply chain and equip every touchpoint in the logistics infrastructure with sensors. Connected vehicles, spaces and goods will gather data throughout the supply chain process and provide customers with much-needed transparency, improve delivery routes and shipping conditions.

Maersk

Maersk was one of the first industry leaders to realize the power of technology in logistics and the need to drive transparency into an increasingly complex and fragmented supply chain. Logistics giant in collaboration with technology companies has developed a variety of applications for container booking, IoT-based shipping management, and tracking.

We know your industry and have both domain and technical experience to help you drive automation and efficiency to logistics operations.

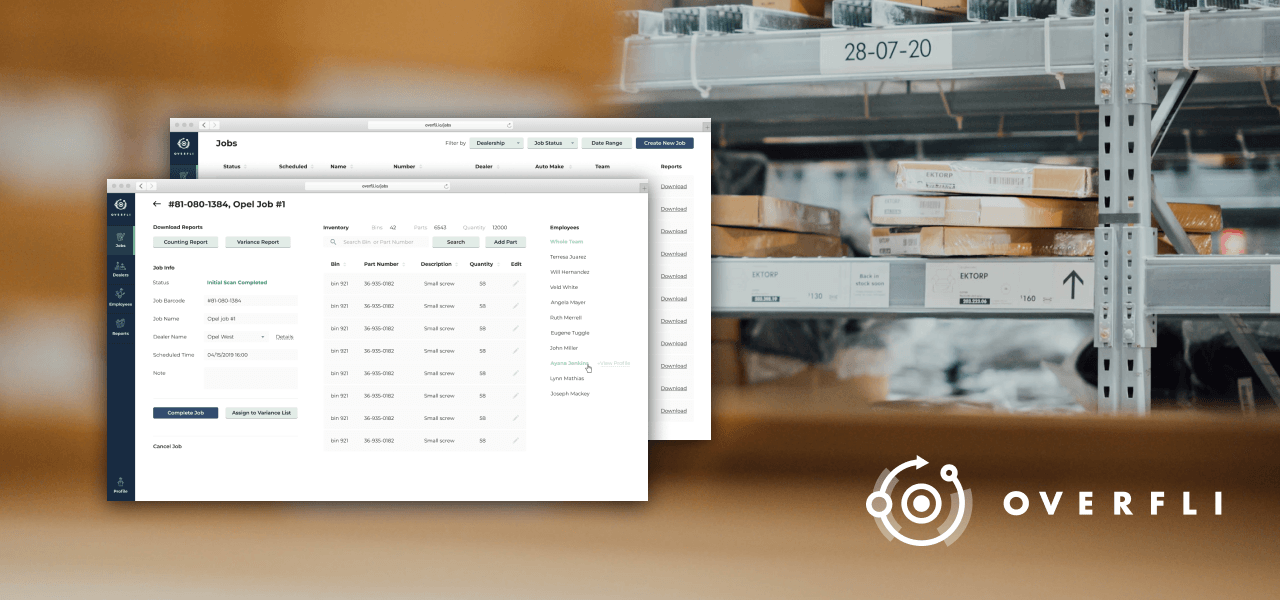

Our team has developed an application for warehouse inventory management for one of our clients in 2019. It is connected to pro scanners for automated inventory, has a mobile app for warehouse staff and a web application for managers to monitor and control the inventory process. Since the application was launched, we have been adding new features and improving the application to help the client increase performance and precision of the inventory process.

There’s no one-size-fits-all when it comes to IoT software development. Project requirements and timelines depend on many factors, including your business objectives, technologies, and market conditions.

If you are looking for a team of professional engineers to help you find the best roadmap for your project and build a custom logistics system fast and effectively, contact Digiteum. Take a look at our case studies to learn more about the Digiteum experience. To get a free consultation, leave a message.

Contact Digiteum

Conclusion

The Internet of Things provides logistics managers with control and transparency they couldn’t have seen coming before. Thanks to real-time data sharing and device-to-device communication, technology can provide insights for improving decision-making and even assist in streamlining deliveries as an independent player.